AGENCY:

Office of the Assistant Secretary for Housing—Federal Housing Commissioner, HUD.

ACTION:

Final rule.

SUMMARY:

This final rule amends the Federal Manufactured Home Construction and Safety Standards (the Construction and Safety Standards) by adopting recommendations made to HUD by the Manufactured Housing Consensus Committee (MHCC), as modified by HUD. The National Manufactured Housing Construction and Safety Standards Act of 1974 (the Act) requires HUD to publish in the proposed revised Construction and Safety Standards submitted by the MHCC. The MHCC prepared and submitted to HUD its third group of recommendations to improve various aspects of the Construction and Safety Standards. HUD reviewed those recommendations and adopted some of them after making editorial revisions and some additions. This final rule further revises the Construction and Safety Standards based on HUD's review and incorporation of certain public comments.

DATES:

Effective Date: March 15, 2021. The incorporation by reference of certain publications listed in the rule is approved by the Director of the Federal Register as of March 15, 2021. The incorporation by reference of certain other publications listed in the rule was approved by the Director of the Federal Register as of August 11, 1987.

FOR FURTHER INFORMATION CONTACT:

Teresa B. Payne, Administrator, Office of Manufactured Housing Programs, Office of Housing, U.S. Department of Housing and Urban Development, 451 7th Street SW, Washington DC 20410; telephone 202-402-5365 (this is not a toll-free number). Persons with hearing or speech impairments may access this number via TTY by calling the Federal Information Relay Service at 800-877-8389 (this is a toll-free number).

SUPPLEMENTARY INFORMATION:

I. Background

The National Manufactured Housing Construction and Safety Standards Act of 1974 (42 U.S.C. 5401-5426) (the Act) authorizes HUD to establish and amend the Federal Manufactured Home Construction and Safety Standards (the Construction and Safety Standards) codified in 24 CFR part 3280. The Act was amended in 2000 by the Manufactured Housing Improvement Act of 2000 (Pub. L. 106-569, approved December 27, 2000) which established the Manufactured Housing Consensus Committee (MHCC), a consensus committee responsible for providing HUD recommendations to adopt, revise and interpret the Construction and Safety Standards. HUD's Construction and Safety Standards apply to the design, construction, and installation of new homes. Changes to the collective standards are not retroactively enforced by HUD as applicable to previously designed, built, and installed homes.

As amended, the purposes of the Act (enumerated at 42 U.S.C. 5401) are: “(1) To protect the quality, durability, safety, and affordability of manufactured homes; (2) to facilitate the availability of affordable manufactured homes and to increase homeownership for all Americans; (3) to provide for the establishment of practical, uniform, and, to the extent possible, performance-based Federal construction standards for manufactured homes; (4) to encourage innovative and cost-effective construction techniques for manufactured homes; (5) to protect residents of manufactured homes with respect to personal injuries and the amount of insurance costs and property damages in manufactured housing consistent with the other purposes of this section; (6) to establish a balanced consensus process for the development, revision, and interpretation of Construction and Safety standards for manufactured homes and related regulations for the enforcement of such standards; (7) to ensure uniform and effective enforcement of Construction and Safety standards for manufactured homes; and (8) to ensure that the public interest in, and need for, affordable manufactured housing is duly considered in all determinations relating to the Federal standards and their enforcement.”

In addition, the amended Act generally requires HUD to establish Construction and Safety Standards that are reasonable and practical, meet high standards of protection, are performance-based, and are objectively stated. Congress specifically established the MHCC to develop proposed revisions to the Construction and Safety Standards. The Act provides specific procedures (42 U.S.C. 5403) for the MHCC process.

The MHCC held its first meeting in August 2002 and began work on reviewing possible revisions to the Construction and Safety Standards. As the MHCC proceeded, proposed revisions to the Construction and Safety Standards were divided into sets. The first set of revisions proposed by the MHCC was published as a final rule in the Federal Register on November 30, 2005 (70 FR 72024). The second set of revisions proposed by the MHCC was published as a final rule published in the Federal Register on December 9, 2013 (78 FR 73965). This final rule is based in part on the third set of MHCC proposals to revise the Construction and Safety Standards published as a proposed rule in the Federal Register on January 31, 2020 (85 FR 5589). The proposed rule included a MHCC proposal to revise the Construction and Safety Standards to reduce the regulatory burden by eliminating the need for manufacturers to obtain special approvals from HUD for certain construction features and options. HUD reviewed the MHCC's proposals and made editorial revisions prior to publishing the January 31, 2020, proposed rule. HUD also added proposals that complement the MHCC's recommendations.

As explained in the January 31, 2020, proposed rule, HUD decided not to include certain MHCC recommendations due to pending regulations for improving energy efficiency in manufactured homes being prepared by the U.S. Department of Energy (DOE) under the Energy Independence and Security Act (Pub. L. 110-140, approved December 19, 2007) (EISA). DOE published a Notice of Proposed Rulemaking on June 17, 2016 (81 FR 39756) and, more recently, a Notice of Data Availability, Request for Information on August 3, 2018 (83 FR 38073) regarding energy conservation standards for manufactured housing. Given this DOE rulemaking, HUD decided to postpone action on MHCC-proposed revisions to §§ 3280.502 and 3280.506(b), except for the mating wall of attached manufactured homes at § 3280.506(b)—an option that is needed to avoid a more burdensome alternative approval process (24 CFR 3282.14—Alternative construction of manufactured homes). HUD also decided not to move forward with a new proposal to add requirements for draftstopping to the Construction and Safety Standards. HUD will not include or move forward with these recommendations in this final rule.

II. Changes Made at the Final Rule Stage

In consideration of the public comments and HUD's experience implementing the program, HUD has made certain editorial revisions to HUD's proposals made in the January 31, 2020, proposed rule. In general, the revisions adopt changes to the codified regulations that reinforce the Act's purposes, namely providing benefits to consumers, homeowners, and the broader community; promoting and improving consumer and home safety; reducing regulatory barriers and expanding consumer options; and allowing use of some for the latest building technologies and materials while creating more consistency with State-adopted residential building codes. HUD declined to adopt some standards or commenters' suggested changes in some instances based on considerations of the statutorily prescribed MHCC process, the lack of authority under the Act for HUD to regulate design and construction of certain types of housing, and consumer safety.

The final rule will revise certain sections of the Construction and Safety Standards, as well as the incorporated reference standards where indicated. The revisions described below are based on HUD's review and consideration of the public comments on the proposed rule, HUD's experience with the program, the existent Construction and Standards, and the issues raised in the proposed rule. The final rule also makes minor technical edits to the Construction and Standards.

§ 3280.5 Data Plate

HUD revised § 3280.5 by revising paragraph (d), pursuant to public comments, to streamline data entry. Paragraph (d) now reads, “(d) This manufactured home IS designed to accommodate the additional loads imposed by the attachment of an attached accessory building or structure in accordance with the manufacturer installation instructions. The additional loads are in accordance with the design load(s) identified on this Data Plate; or This manufactured home IS NOT designed to accommodate the additional loads imposed by the attachment of an attached accessory building or structure in accordance with the manufacturer installation instructions.” The appropriate designation may be made while still setting forth information that may be used by state and local authorities that have enforcement authority for site-built structures that are not integral to the manufactured home produced and shipped by the manufactured home manufacturer. HUD seeks to preclude a home from being taken out of compliance when an attached accessory building or structure is built and added on at the home site.

§ 3280.108 Interior Passage

HUD revised paragraph (c) in this section in accordance with the public comments by creating an exception to the requirement for doors to closets, pantries, and doors to toilet compartments in single-section homes. Single-section manufactured homes have a smaller living space when compared with a multi-section manufactured home or a typical site-built home and, thus, closet and pantry doors should not be subject to the same clear opening requirements as a multi-section manufactured home or a typical site-built home.

§ 3280.114 Stairways

HUD adjusted the rise and run dimensions based on public comment. The changes recommended by public commenters on the proposed rule will give manufacturers more flexibility when trying to balance the smaller form-factor of most homes with consumer demand for multiple stories. The edits clarify that the standards do not apply to exterior stairways that are built at the home site or stairways to basement areas that are not designed and built as part of the manufactured home.

§ 3280.209 Smoke Alarm Requirements

While HUD did not revise this section in the proposed rule, a public commenter recommended that combination smoke and carbon monoxide alarms be added as acceptable devices to parallel the International Residential Code (IRC). Furthermore, the changes to this section are intended to work in conjunction with the changes to § 3280.211.

§ 3280.211 Carbon Monoxide Detectors

“Alarms” and “detectors” are different items that serve different purposes. HUD changed references from “detector” to “alarm” in response to public comment. HUD also revised this section to include specific locations where such items must be installed rather than just referencing the more general standards, such as the National Fire Protection Association Standard 720.

§ 3280.212 Factory Constructed or Site-Built Attached Garages

Public commenters suggested that the distinction between attached and self-supported structures be emphasized in this section. HUD clarified that paragraph (a) applies only to garages which are not self-supported and revised the fire separation requirements in paragraph (c), including that the garage must be separated from the home with appropriate gypsum wallboard or equivalent. HUD also added paragraph (h) as suggested by public comment to include that a site-built, self-supported garage is considered an add-on subject to § 3282.8(j)(1) and state and local authorities.

§ 3280.213 Factory Constructed or Site-Built Attached Carports

Similar to the previous section, public commenters also suggested that the distinction between attached and self-supported structures be emphasized in this section. HUD made several changes to this section based on public comment, including adding a provision in paragraph (b) that the manufacturer may provide the maximum live and dead loads, and the applied loading locations that the home is designed to resist from the carport, and other design limitations or restrictions.

§ 3280.504 Condensation Control and Installation of Vapor Retarders

Based on public comment, HUD clarified the distinction between mating walls and fire separation walls in paragraph (b), stating that the fire separation wall between each attached manufactured home must be considered to be an exterior wall pursuant to subpart K.

§ 3280.609 Water Distribution Systems

In order to better protect residents, HUD added relief pipe turndown requirements to this section based on public comment, stating that exterior relief drains shall be directed down and shall terminate between 6″ and 24″ above finished grade. This is high enough to prevent backflow, but low enough to reduce the risk of injury or accident.

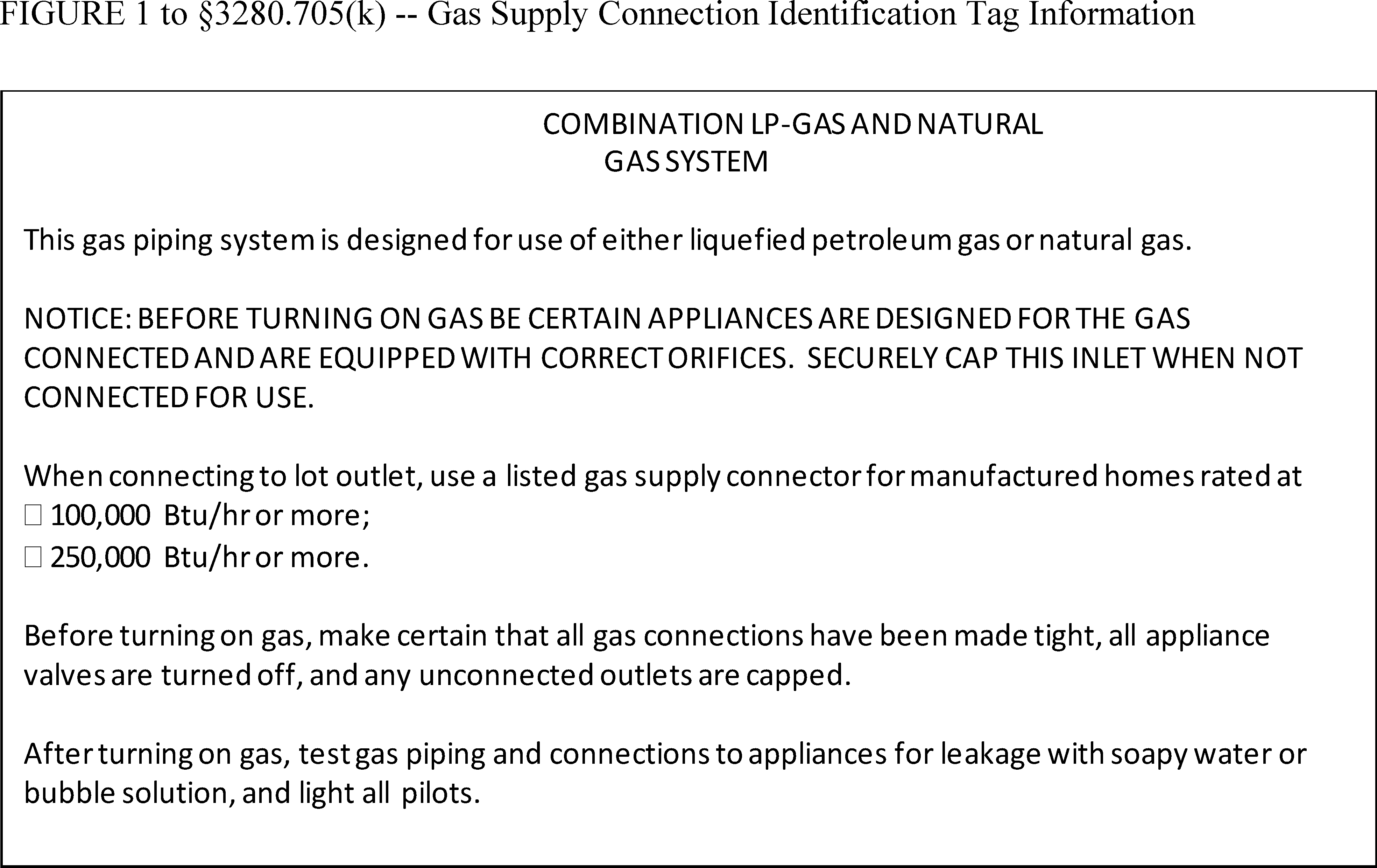

§ 3280.705 Gas Piping Systems

HUD eliminated “hard pipe” in paragraph (I)(8)(iii), to account for a flex gas connector rather than a quick-disconnect.

§ 3280.710 Venting, Ventilation, and Combustion Air

HUD clarified that the placement restrictions apply to exhausts of fuel burning appliances and used the defined term “habitable rooms” in this section. This provides consistency across the regulation.

§ 3280.904 Specific Requirements for Designing the Transportations System

In addition to some language and grammatical changes, HUD added a requirement to check weights with the home in a level position ready for transport in paragraph (b)(4)(ii), an explicit reference to the Department of Transportation's regulations at 49 CFR 393.52(d) in paragraph (b)(9)(ii) regarding stopping distance, and textual changes to paragraph (b)(9)(iii) regarding electrical brake wiring.

§ 3280.1002 Definitions

In this section, HUD edited the definition of “Fire separation wall” to emphasize the separation between attached manufactured homes.

§ 3280.1003 Attached Manufactured Home Unit Separation

HUD clarified this section based on public comment, particularly in paragraph (a)(1) related to fire resistance. These edits will help HUD address minimum fire separation requirements for common walls of attached manufactured housing solutions in the Standards.

III. The Public Comments

The public comment period for the January 31, 2020, proposed rule closed on March 31, 2020. HUD received forty-one (41) public comments in response to the proposed rule, from various manufactured home associations, non-profit organizations, and other interested parties. This section presents the significant issues, questions, and suggestions submitted by public commenters, and HUD's responses to these issues, questions, and suggestions.

Most commenters supported updates to the Construction and Safety Standards, and encouraged HUD to continue working on updates to, and provided specific recommendations for, certain sections of the Construction and Standards. For example, several commenters supported adding two-family or two- and three-family dwelling units to the new Subpart K, Attached Manufactured Homes and Special Construction. Some commenters also suggested deleting or removing certain changes proposed by HUD. For example, some commenters opposed or requested clarification of HUD's proposed changes to stair rise and run requirements, and suggested changes to create consistency among the Standards' landing requirements and clarify whether certain requirements apply to stairs inside, or inside and outside, the home.

The following sections summarize the comments received on the proposed rule and HUD's responses:

General Support

The majority of commenters expressed general support for the proposed changes as part of HUD's effort to update the Construction and Safety Standards. These commenters stated that the proposed changes would benefit homeowners and the broader community, promote or improve consumer and home safety, allow use of the latest building technologies and materials, create more consistency with State-adopted residential building codes for site-built housing, expand consumer amenity options (including attached garages, carports, decks and accessory buildings), help to include two-story and multifamily guidelines, and eliminate regulations that impede broad access to affordable housing. Several commenters also urged HUD to move forward with publishing the next set of proposed updates to address outstanding items.

HUD Response: HUD agreed with the commenters that the proposed changes would provide benefits to consumers, homeowners, and the broader community, and help promote the other purposes and policies of the National Manufactured Housing Construction and Safety Standards Act of 1974.

Comment: Testing requirements should be included but be accredited to ISO/IEC 17025 or 17020 by accredited testing laboratories that are signatories to the International Laboratory Accreditation Cooperation Mutual Recognition Arrangement (ILAC MRA).

One commenter stated that several parts of the proposed rule reference testing, such as American Society for Testing and Materials, Standard Test Methods for Fire Tests of Building Construction and Materials (ASTM E 119), and recommended that these laboratory tests be conducted by ISO/IEC 17025 accredited testing laboratories so as to be assured that the testing results are generated by an entity that has been found to be technically competent by an independent, accreditation body. Two commenters supported testing requirements, but recommended that these laboratory tests be accredited to ISO/IEC 17025 or 17020 by accredited testing laboratories that are signatories to the International Laboratory Accreditation Cooperation Mutual Recognition Arrangement (ILAC MRA), to assure that the testing results are generated by an entity that has been found to be technically competent by an independent accreditation body. One commenter added that this would allow HUD to focus resources on program oversight and/or research for technical advancements. The commenter provided a link to an example of effective models whereby government agencies rely on ISO/IEC 17020 accreditation programs (https://www1.nyc.gov/site/buildings/industry/recognized-accrediting-bodies.page).[1]

HUD Response: HUD disagreed with the commenters. HUD's regulations at 24 CFR 3280.2 require products to be listed, certified, or labeled by a nationally recognized testing laboratory, inspection agency, or other organization concerned with product evaluation that maintains periodic inspection of production of labeled equipment or materials, and by whose labeling indicates compliance with nationally recognized standards or tests to determine suitable usage in a specified manner. HUD also believed that this recommendation should be submitted for MHCC review and consideration, that it is not appropriate for HUD to integrate these changes at this final rule stage, and the commenter should make the proposal through the MHCC process through the following website: http://mhcc.homeinnovation.com/.[2]

Comment: HUD should adopt universal design standards.

A commenter who identified as a person with a disability recommended that HUD adopt universal design standards in manufactured home construction and encourage communities and housing agencies to do likewise.

HUD Response: HUD appreciated the commenter's perspective that HUD adopt universal design standards. While HUD is fully supportive of the need for affordable and accessible housing, it noted that universal design can be accomplished within the minimum Construction and Safety standards requirements already codified. Further, many home manufacturers currently offer homes designed and constructed to meet universal design standards without conflicting with HUD's current minimum standards.

General Opposition

Some commenters stated that the several of the provisions proposed would increase manufactured home installers' liability and responsibility if the proposed rule is advanced without significant change. The commenters stated home installers were not included in deliberations, and, as such, HUD should not move forward with this rule.

HUD Response: HUD disagreed with the commenter that manufactured home installers were not included in deliberations. The MHCC membership has included and continues to include representation from at least one individual with manufactured home installer interest. The MHCC process is administered in an open format in which any member of the public, including manufactured home installers, may participate and address the Committee, as well as propose changes for MHCC review. All such meetings are published in the Federal Register at least 30 days in advance of meetings.

Comment: Manufacturer Documentation.

One commenter stated that the proposed rule's requirements for the manufacturer to provide documentation poses problems, because HUD does not require inspection agencies to check any of the documents the manufacturer provides in the home. The commenter stated this situation resulted from HUD's Interpretative Bulletin H-1-77,[3] which the commenter asserted complicates several proposed changes, namely those at §§ 3280.212, 3280.213, 3280.612, and 3280.709. The commenter stated that if the proposed rule becomes final, HUD should rescind Interpretive Bulletin H-1-77 to account for the installation program loophole and the failure to provide assurance that the proper documentation would be shipped with the home. Another commenter stated a concern with potential liability for installation work related to accessory buildings and other on-site installation, such as certain appliances the proposed rule states can be shipped “loose” to the homesite. According to the commenter, to ensure that the end buyer or resident of the home has a home that has been safely manufactured, transported, and installed, it is vital that all installation documentation is shipped with and remains with the home.

HUD Response: HUD is aware that standards for some construction features that are addressed in this rulemaking affect the installation process and therefore impact the responsibilities of home installers. All construction features included in this final rule were previously available through the Alternative Construction process and in all instances where an Alternative Construction letter had been issued, HUD required specific documentation to be provided with each affected manufactured home, including installation instructions. The same or similar documentation would continue to be required pursuant to the requirement for manufacturers to provide installation instructions in accordance with 24 CFR 3280.306(b) and 24 CFR 3285.2. Further, the home manufacturer instructions must provide minimum installation specifications so that the home is not taken out of compliance with the Construction and Standards and meets the Model Manufactured Home Installation Standards. These instructions are reviewed and approved by HUD-approved Design Approval Primary Inspection Agencies (DAPIA) and manufacturers are required to provide the instructions with each manufactured home.

HUD also disagreed with the commenter that requiring the manufacturer to provide the instructions, without requiring an inspection to verify the instructions are shipped with the home, complicates matters or otherwise poses risks to consumer health and safety. The manufacturers' installation instructions and documentation are required to be reviewed and approved by its DAPIA to help ensure conformance. Further, it is the manufacturers' responsibility to ensure that each home is provided with installation instructions and associated documentation as approved by its DAPIA. DAPIA-approved quality assurance manuals typically require manufacturer verification for the shipment of the installation instructions. It is the IPIA's responsibility to ensure the effectiveness of the quality assurance manuals. HUD may review and reconsider this matter further should evidence showing appropriate installation instructions are not being shipped with manufactured homes. The commenter(s) should submit proposed regulatory text through the MHCC process at http://mhcc.homeinnovation.com/ so that the matter is reviewed by the MHCC.[4]

Comment: HUD should not use sub-regulatory guidance to establish Construction and Safety standards.

A commenter stated that HUD should repudiate the use of sub-regulatory “guidance” or “field guidance” memoranda and documents to establish de-facto manufactured housing “standards.”

HUD Response: HUD is currently implementing Executive Order 13891, Promoting the Rule of Law Through Improved Agency Guidance Documents,[5] and this comment is not applicable to any aspect addressed in this rulemaking.

Comment: HUD should not provide competitive advantage to any housing type.

Another commenter expressed concern regarding any policy that may give one housing type an unwarranted competitive advantage and risks the occupants' health and safety. The commenter stated HUD should refrain from making any changes that would result in furthering the divide between the code requirements for manufactured homes and those that apply to homes that are stick-built or built using engineered building systems. The commenter urged HUD to maintain this balance and continue to facilitate consumer choice by ensuring that regulatory reform efforts do not favor manufactured homes over other residences, leading to consumer confusion and unfair marketplace competition.

HUD Response: HUD's authority to develop and implement standards is applicable only to homes meeting the statutory definition of a manufactured home. However, this rulemaking brings the Standards in closer alignment to standards imposed for other types of housing.

Comment: HUD has no authority to establish standards for structures attached to a manufactured home.

A commenter stated that HUD defined “manufactured housing” narrowly in § 3280.2 to mean a structure built on a permanent chassis and designed to be used as a dwelling. The commenter stated that while HUD has authority to establish requirements applicable to components within the chassis, it does not have the authority to establish standards for items outside or apart from the chassis. Rather, authority to regulate these structures rests with state and local authorities and their building code requirements and inspection protocols. “Add-on or accessory buildings or structures” are not built on a permanent chassis. Section 3285.903 provides conditions where add-on or attached accessory buildings or structures may be installed, but again fails to designate inspection responsibilities. The definition for “Attached accessory building or structure” proposed for addition to §§ 3280.2 and 3285.5 further adds to the confusion indicating that it includes such items when they are designed for attachment and structural support from the manufactured home.

HUD Response: HUD's standards developed and implemented through this rulemaking are not intended to apply to the design and construction of site-built structures, including add-ons (in other words, the site-built garage, or the site-built carport). However, the standards and regulations established through this rulemaking do apply to the design and construction of the manufactured home, when the home is designed to have an attached accessory structure, such as the garage, carport, or similar add-on. The requirements established are to ensure that the manufactured home will continue to comply with the Construction and Safety Standards and that the residents' health and safety will be protected through means such as adequate structural load design and minimum fire separation and other requirements when applicable. The design, construction, and inspection of the attached accessory structure (site-built garage, site-built carport, or other site-built add-on) remains subject to any applicable state and or local requirements.

Subpart A, General

§ 3280.2 Definitions

One commenter opposed the definition change to “attached accessory building or structure,” while another commenter supported the proposed changes. Some commenters stated that proposed definition of “Attached accessory building or structure” fails to include stairs, which are needed for entry in almost every manufactured home.

One commenter further stated that the proposed rule would require that the “basic manufactured home” be designed for the attachment of these structures. This does not address the need for the manufacturers to modify their installation instructions to reflect the added weight and wind load that added structures would impose on the home's foundation.

Another commenter stated that the definition appears to open the flood gates for other additions to a manufactured home which can affect egress requirements as well as alter the electric, heating, plumbing and other systems. The commenter provided examples; awnings, porches, and ramadas typically are identified as a covered area projecting in front of an entrance, while cabanas are defined as a cabin, hut, or shelter, and garages are defined as a “building” for housing a motor vehicle. The commenter stated that these are totally separate structures which affect the home differently and can create safety hazards. The commenter suggested that the proposal should be rewritten, and garages should be addressed separately.

A commenter stated that the term “basic manufactured home” is not defined and pre-supposing that there is such a thing as a “non-basic manufactured home.” If this is the case, HUD should clearly indicate what they mean by these terms and how the construction and safety standards would apply. The commenter contended that regardless of HUD's differentiation in this case, the manufactured housing Construction and Safety standards should be applied consistently and any manufactured home, whether deemed “basic” or “non-basic” be clearly marketed as a manufactured home to avoid customer confusion and an expectation of the product being received.

HUD Response: HUD disagreed with commenters stating that HUD should establish requirements for stairs external to the manufactured home, which are needed for entry in most manufactured homes. HUD's established standards only govern the design and construction of the manufactured home, including all provisions addressed by this rulemaking. Requirements for external stairs that are necessary to provide entry to the homes remain subject to design and construction requirements of state and local jurisdictions as they are not intended to increase the living or storage area of the manufactured home and are dependent upon the siting and installation of each individual home which may vary by model, lot size, topography, and other aspects.

HUD agreed with the commenter stating that the proposed rule would require that the manufactured home be designed for the attachment of these site-built structures. However, HUD disagreed that the manufacturer would not be required to provide installation instructions that reflect the added weight and wind load that an added structure would impose on the home's foundation. HUD's standards, set forth at § 3285.903, require accessory structures to be structurally independent unless the attached accessory building or structure is otherwise included in the installation instructions or designed by a registered professional engineer or registered architect. Further, the changes to the Data Plate specifically identify when the home is designed for an attached accessory structure, and if so, the loads the home has been designed to accommodate (see § 3280.5).

HUD disagreed with the comment suggesting that the definition of accessory building or structure is too broad. The Construction and Safety standards address the design and construction of the manufactured home and do not address the design, construction, placement, or other standards for the design and construction of the accessory structure(s). Further, state and local authorities may verify that a home has been designed for an attached accessory structure by verifying such information available on the Data Plate. HUD agreed with the commenter that the term “basic manufactured home” is not defined; therefore, “basic” has been removed.

§ 3280.5 Data Plate

One commenter opposed the proposed rule's changes to the Data Plate language and another commenter supported the proposed changes. Some commenters agreed, however, that certain modifications to the Data Plate definition should be made: The Data Plate indicates whether the home is designed to accommodate an add on, accessory building, and the like, and the Data Plate and other documentation should document the weight, size, and other limits the manufactured home can support. Failure to require additional information will lead to confusion and result in many homes being stressed beyond their designs limits and therefore lead to structural failure. Another commenter stated that the manufacturer should be required to identify the maximum loads applied to the floor system, wall system, roof system and support system.

Another commenter suggested HUD delete the first paragraph of the applicable statement in § 3280.5(d). This and another commenter recommended HUD revise the second paragraph to include a checkbox for “is” or “is not” similar to current language for § 3280.5(g) to reduce language and clutter on home Data Plates. One commenter explained that this alternative would still capture the intent of HUD's proposal, while preserving space on the Data Plate for future statements or other required disclosures. The commenters proposed significant changes to HUD's proposed regulatory text.

HUD Response: HUD considered all comments received on the requirements for the Data Plate and made minor changes to reflect and accommodate some of the comments. Through the language on the Date Plate, HUD is trying to provide information to the consumers, retailers, installers, and local authorities about the design and construction of the home that may help prevent a home from being taken out of compliance when an attached accessory building or structure is built and added on at the home site. Further, the Data Plate provides information that may be used by state and local authorities that have enforcement authority for site-built structures that are not integral to the manufactured home produced and shipped by the manufactured home manufacturer.

Subpart B, Planning Considerations

One commenter stated that HUD proposed to adopt a superseded MHCC recommendation concerning ventilation. HUD has proposed to authorize manufacturers' compliance with the 2010 edition of American Society of Heating, Refrigeration, and Air-Conditioning Engineers (“ASHRAE”) Standard 62.2, “Ventilation and Acceptable Indoor Air Quality in Low-Rise Residential Buildings,” as an alternative to the prescriptive ventilation requirements in § 3280.103(b) and (c). The proposed rule ignores that more than four years ago, the MHCC updated its recommended acceptance of ASHRAE Standard 62.2 to refer to the 2013 version. Adopting the more recent version of the ASHRAE standard in this rulemaking would avoid the need for an additional change to the regulations later to update the reference.

HUD Response: HUD understands that the MHCC continues to provide recommendations that may be more recent than those published in proposed rules, including updates to the referenced ASHRAE Standard 62.2. Generally, HUD finalizes recommendations in the order received to avoid selective choice, minimize confusion, and so that full and complete impact analyses can be conducted specific to the various groups of recommendations provide by the MHCC.

§ 3280.103 Light and Ventilation

One commenter supported the removal of the maximum 90 cubic feet per minute fan requirement, which will allow the commenter to increase the size of homes built to accommodate larger families, which commenter stated will allow more families to live in safe, affordable homes with the modern amenities they desire.

Another commenter expressed concern that using the Standards and eliminating the alternative construction (AC) process for manufactured housing that utilizes design elements of site-built homes could affect the manufactured housing occupants' health and safety. The commenter urged HUD to keep the AC process in place for design features that could affect the manufactured home's structural integrity and safety, including attached homes (i.e., zero lot line), multi-story homes, and attached carports and garages. The commenter continued that blurring the line between what is manufactured housing and what is site-built housing could mislead homebuyers, and that manufactured housing that emulates site-built elements should be held to the same inspection and building standards as site-built homes. The commenter urged HUD to require attached units to meet all state and local building codes, including higher energy standards, required for conventionally built housing.

HUD Response: HUD's minimum requirements established for attached homes (i.e., zero lot line) and multi-story homes do not change the definition of a manufactured home or impact the requirement that every transportable section of a manufactured home bear a manufacturer's certification label. Through this rulemaking, HUD is codifying requirements previously set forth through Alternative Construction requirements; thereby, accounting for consumer safety. All regulatory aspects of the program, including design review and inspections, remain in place for all manufactured homes built under this federal program. HUD believes the minimum standards established and enforced for these construction options provide benefits to all segments of the industry while protecting consumers' health and safety. Further updates to the referenced ASHRAE Standard 62.2 may be addressed in future rulemaking.

§ 3280.108 Interior Passage

Several commenters agreed that clarification was needed regarding to which doors the 27-inch requirement applies. One commenter stated that closet doors (including walk-in closets) and pantry doors are less than 27-inches, typically 24-inches or less. Another commenter stated that it has several floor plans with closet and pantry openings less than 27-inches and uses 24-inches for water heater and furnace compartments and 16-inches for linen and coat closets. The commenters stated that they would need to make significant changes to floor plan designs to accommodate HUD's proposal, and one commenter explained this would add costs to the home, drive up affordable housing costs, and financially burden the commenter. One commenter suggested clarifying that the minimum clear opening requirement of 27-inches only apply to passage doors in a manufactured home.

Some commenters suggested adding exclusions for closet, pantry, coat closet, linen closet, and toilet compartment doors and other spaces where the intent is to “reach in” and access an item. The commenters explained that closet and pantry doors, unlike a bedroom door, are not considered passage doors. Further, single-section manufactured homes have a smaller living space when compared with a multi-section manufactured home or a typical site-built home. Given that living space is at a premium in single-section homes, closet and pantry doors should not be subject to the same clear opening requirements.

HUD Response: HUD agreed with the comments and revised the standard accordingly.

§ 3280.111 Toilet compartments

Two commenters suggested revising language in paragraph (b) to clarify the regulatory intent that the section refers to bathroom passage doors in single-section and multi-section homes. For example, the term “single-section” should modify “home,” not “bathroom.”

HUD Response: HUD agreed with the comments and revised the standard accordingly.

§ 3280.114 Stairways

Comments: Riser Height, Tread Depth, and Consistency.

Several commenters opposed HUD's proposed changes to stair rise and run requirements. Some commenters noted that, as written, the proposal would conflict with existing state and local requirements and require manufactured home communities to replace existing inventory of prefabricated landings and stairs. Another commenter stated that the stair rise and run in HUD's proposed rule would not allow stairs to be run parallel with the width of many homes, which would eliminate many floor plan options and adversely penalize manufactured home builders.

One commenter stated that, § 3280.114(a)(2)(i), 7″ risers and 10″ treads would cause stairway openings to be larger to the point where some floor plans would no longer accommodate a stairway. Some commenters suggested HUD use 8″ or 8.25″ for the maximum rise and 9″ for the minimum tread, which are figures that thirteen states accept.[6] One commenter also suggested HUD change “%” to “3/8 inch” in § 3280.114(a)(2)(i), and change “%” to “3/4 inch” in § 3280.114(a)(2)(ii). This commenter also suggested changing “Y2” to “1/2 inch” in paragraph (a)(5).

According to another commenter, the maximum riser height and minimum tread depth should be changed to 81/4 inches and 9 inches in § 3280.114 (a)(2)(i). HUD's proposed requirements would almost eliminate stairway designs that run parallel with the width of a traditional manufactured home. This commenter's rationale for the recommended change included giving manufacturers more flexibility when trying to balance the smaller form-factor of most homes with consumer demand for multiple stories.

HUD Response: Regarding riser height and tread depth, HUD reviewed several state building codes referenced in public comments and has made changes to riser height and tread depth consistent with those requirements found in many state building codes and in accordance with the comments received.

Comments: Interior and Exterior Stairs.

Several commenters stated that HUD should clarify whether the requirements apply to stairs inside, or inside and outside, the home or commented on whether the requirements should apply to these different sets of stairs. One commenter stated that requirements for stairways and related design features should focus only on stairways placed inside the manufactured home, and the section title should be changed to “Stairways Inside the Manufactured Home.” Another commenter stated that the proposed changes to paragraph (a)(2) addresses interior stairways and exterior stairways; the commenter suggested revising the proposal to address interior steps only. According to the commenter, states and local municipalities establish stair geometry to which first responders are already accustomed, and to require smaller riser heights and larger treads may create a hazard.

Another commenter supported the addition of language to define requirements for stairways, landings, handrails, guards, and stairway illumination, however, the commenter suggested the language should detail if it covers interior stairways, exterior stairways, or both.

Another commenter suggested striking paragraph (b)(2) in its entirety because it partially conflicts with paragraph (b)(1), or, if HUD disagreed with striking (b)(2), revising (b)(2) as follows to streamline and clarify requirements: “A landing or floor must be located on each side of an exterior doorway and the width of each landing must not be less than the door it serves. The maximum threshold height above the floor or landing must be 11/2 inches.” Given that paragraph (b)(1) addresses interior stairways, doors, and landings (with exception for certain basement applications), the commenter assumed that paragraph (b)(2) must be intended for exterior applications, which is the basis for the suggested edits.

Two commenters suggested HUD delete paragraph (e)(2) entirely, since exterior stairs are not constructed within the building facility and more appropriately fit under the HUD Code's Model Manufactured Home Installation Standards. A commenter explained that exterior stairs would be subject to state and local building code and health-safety requirements. If HUD's exterior illumination requirements conflict with state or local requirements, it would only cause confusion within the industry and may put consumers at risk.

Comment: Guard Rails.

Some commenters also suggested, for § 3280.114(d)(1), that the proposed load requirements only apply to guards more than 42″ above the floor grade below, to prevent driving up housing costs without providing significant increased safety protection. When a manufactured home includes a porch or similar feature, once installed, it is usually between 30 and 42 inches above the lower floor, and there is no evidence of increased injury from a fall as a result of a guard failure that is 42 or fewer inches from grade. The commenters provided regulatory text edits, and stated that a 30-inch guard rail structural requirement would increase the cost of each single-section home with a modest porch by $500, or more for larger homes, which undermines HUD's efforts to preserve manufactured housing affordability.

The commenters further stated HUD should remove the language regarding the horizontal rail restriction in paragraph (d)(2), which HUD has not backed with a significant health-safety concern as justification and which would restrict designs and add unnecessary cost. This restriction is not found in the International Residential Code (IRC), which only prohibits the passage of a four-inch sphere and would result in a restriction for manufactured home builders that does not exist for site-built home builders. One commenter stated that IRC Table R301.1.5 does not require the 200 pound concentrated load to be applied with any other loads and, therefore, the word “not” should be added after “this load” in the last sentence of paragraph (d)(2)(ii). Another commenter agreed and added that this makes (d)(2)(ii) consistent with the last sentence in paragraph (c)(5).

Comment: Lighting.

For § 3280.114(e)(1), one commenter stated that HUD should delete the requirement for artificial light to be not less than one-foot-candle at the center of treads and landing and require only a light above stairways and landings because the commenter was not aware of a test method. Another commenter suggested a prescriptive method to simplify compliance with interior stair lighting. Lumens required for a 3 feet wide x 9 feet vertical stair would be 3 feet x 11.67 feet x 1 foot-candle = ~35 Lumens. One 60-watt incandescent bulb or 10-Watt A19 LED provides about 840 lumens which is more than adequate.

Another commenter recommended HUD add a prescriptive lighting standard as an alternative compliance option. The proposed illumination requirement of “not less than one (1) foot-candle measured at the center of treads and landings” creates a new test requirement, but it is unclear who is responsible for performing the test and assessing compliance. Without an explanation of the test parameters and how the test would be administered, the commenter was concerned this provision would be inconsistently enforced. As an alternative, the commenter recommended that HUD introduce a minimum standard for illumination.

HUD Response: Generally, HUD agreed with most comments and made changes to the standards for stairways including revisions to riser height and tread depth (§ 3280.114(a)(2), clarification of interior and exterior consideration (§§ 3280.114(a) and 3280.114(b)), provisions for landings (§ 3280.114(b)), and handrails (§ 3280.114(c)).

HUD also modified the standard in multiple places so that the text reflects HUD's regulatory authority for design and construction of the home and its lack of authority to regulate stairways that are designed by others and built at the home's site necessary for access and egress from the entry and exit points of the homes. HUD also disagreed with some commenters, as the requirements in § 3280.112 only apply to stairways integral to the manufactured home, such as those necessary for multi-story or multi-level manufactured home floors or for stairs that are not inside the home but may be necessary for multi-level manufacturer designed and constructed porches designed and built in the home building factory as an integral feature of the manufactured home. Further, requirements for external or exterior stairs that provide entry and exit and are built at the home site are subject to state and or local authority and any such reference otherwise has been removed.

HUD modified the standards related to landings removing duplicative language, clarifying interior versus exterior provisions, and threshold height.

HUD also modified the standard regarding handrails to be consistent with requirements for handrails (removal of ladder effect restriction) identified in other building codes for other residential structures. However, HUD disagreed with comments that would have changed the load requirements for guard systems to apply only to guards above 42 inches above floor grade.

The changes effected by this rule are generally consistent with other residential codes enforced nationwide. However, the load requirement of 20 pounds per square foot is significantly less than the load required by many states for similar guard systems.

After consideration of the public comments, HUD has not changed the stairway and landing illumination requirements from the proposed rule as commented by multiple commenters. The requirements, as published, are consistent with state and local standards and compliance remains, as with all other standards, the responsibility of the home manufacturer. In section I. of the preamble to this rule, HUD clarified that all standards in this rule are not retroactive and apply only to newly constructed homes that enter the first phase or stage of production on and after the effective date of the rule. Further changes, such as those proposed by some commenters, should be proposed for review by the MHCC so that consensus review of those proposed changes is made as envisioned by the Act. It is not appropriate for HUD to integrate these changes at the final rule stage.

Subpart C, Fire Safety

§ 3280.209 Smoke Alarm Requirements

One commenter recommended HUD revise § 3280.209, a section not addressed in the proposed rule. The commenter stated that HUD should add combination smoke and carbon monoxide alarms as acceptable devices just as they are in IRC sections R314.1.1 and R314.5.

HUD Response: HUD agreed with the commenter and made the corresponding change.

§ 3280.211 Carbon Monoxide Detectors

Some commenters supported incorporating carbon monoxide requirements into the Standards to protect consumer health and safety. One commenter noted that the MHCC made this recommendation in 2009 and HUD should have adopted it some time ago.

One commenter suggested HUD should revise § 3280.211 to include specific location requirements like smoke alarms, instead of referencing the National Fire Protection Association (NFPA) Standard 720.

Some commenters stated that the proposed rule's coverage of CO alarm requirements would be insufficient under the new § 3280.211 in protecting occupants of manufactured housing because of its limited coverage. All manufactured housing should have CO alarms and not just those with fuel-fired appliances, designed for installing attached garages, or designed for installation over basements. While the new § 3280.211 would be consistent with occupancy-related installation requirements of IRC Section R315, these requirements provide no direct protection for occupants of manufactured homes except where coincident housing-related factors of installed fuel-fired appliances, designs for installing attached garages, or designs for installation over basements were relevant. Furthermore, the proposed § 3280.211 requirements would not protect occupants where other sources such as use of portable heating appliances or from misuse of charcoal grills indoors (both reflected in CO incident data) following completion of manufactured housing installation and commissioning. Occupants of “all-electric” homes may be particularly vulnerable during periods of electrical outage. The comment provided instances of harm caused by carbon monoxide.

One commenter commended HUD for recognizing the importance of requiring carbon monoxide detectors consistent with the IRC's requirements. Through incorporation into the Construction and Safety Standards, HUD relieves local officials from conducting additional inspections and potential re-work post installation to comply with local requirements.

Another commenter stated that HUD's proposed carbon monoxide requirements should align more closely with similar requirements in other building codes, such as the IRC's. Specifically, the commenter's suggestions include: Specifying the required locations where carbon monoxide alarms must be installed (for example, alarms should be required outside each separate sleeping area or in the immediate vicinity of any bedrooms); requiring interconnectivity between alarms, because when more than one alarm is installed in a home, the actuation of one alarm should activate all alarms; specifying how each alarm must be powered, because the home's electrical system should be the primary power source, with batteries as a secondary, reserve power source; and clarifying that the Standards would allow combination carbon monoxide and smoke alarms to keep pace with consumer demand. Another commenter (0023) also supported this change.

According to the commenter, HUD should clarify that combination alarms are acceptable to ensure the industry continues to keep pace with consumer demand. The commenter also suggested amending § 3280.209 to ensure the sections cross-reference each other.

Comment: Alarms versus Detectors.

Some commenters stated that the word “detector” should not be used and suggested using “alarms” to be consistent with other codes and striking the word “detector” wherever it occurs, because alarms and detectors are distinct concepts. Alarms are self-contained, single, or multi-station sensing devices that detect a given event and sound an audible or visual alarm. Detectors are sensing devices that must be connected to a separate alarm system, rather than self-contained systems. One commenter stated that standards do not include requirements for transmitting detection devices to an alarm control unit as would be necessary with detector devices. The commenter recommended removing the standard versions in specific code sections which are incorporated by reference in § 3280.4, which will allow for simplified future updates and is a common practice for incorporating building code standards into regulations and laws. The commenter recommended removing the reference to ANSI/UL 2034, which may not be readily available and incorporate location requirements within this section.

HUD Response: HUD agreed with many comments and has modified the Construction and Safety Standards to address combination alarms, integration of specific location requirements, and removal of references to “detector.” HUD also notes that updating specific editions of referenced standards may require notice and comment and as such, will remain for the time-being. HUD also disagreed with some commenters that proposed to require carbon monoxide alarms in all homes, regardless of whether the home as fuel-burning appliances, an attached garage, or designed for installation over a basement. HUD's standards are consistent with state and local standards for residential construction. Should the commenter wish to pursue requirements for carbon monoxide alarms in all homes, the commenter is encouraged to submit the proposed change to the MHCC for review and deliberation by the Committee. It is not appropriate for HUD to integrate these changes at the final rule stage.

Subpart C, Fire Safety, Attached Garages

§ 3280.212 Factory Constructed or Site-Built Attached Garages

One commenter noted that HUD's current policy, to not require the IPIA to inspect documents shipped with the manufactured home (under Interpretive Bulletin H-1-77), conflicts with proposed paragraph (g)—there is no assurance that the manufacturer would be including these additional instructions.

A commenter stated that the proposed rule leaves it unclear as to when a garage is to be added to the home. Another commenter stated that HUD should clarify that paragraph (a) applies only to garages which are not self-supported. One commenter supported HUD's actions to remove the issue of attached garages and carports from the costly AC process. The commenter stated that the proposed standards and regulations would effectively obviate previous sub-regulatory HUD “guidance” memoranda which mandated the approval of attached garage and “add-on”-ready manufactured homes via the AC process set forth at § 3282.14.[7]

Several commenters stated that HUD should revise the proposed fire separation requirements. A commenter stated HUD should require that gypsum be added on site to meet the fire separation requirement. Installing gypsum on the exterior of a home in the factory would not be a durable enough exterior finish for storage and shipping. Another commenter agreed and stated that paragraph (c) needs to be clarified so that fire separation between the garage and the home may be completed on-site. Site-installed dormers at the garage in addition to floor-to-foundation fire separation will be required to be completed on-site and it would be advantageous to run all separation at that time to ensure proper alignment with the garage. Paragraph (c)(1) should also be clarified to allow gypsum required to meet separation to be either factory or site installed and allowance for products equivalent to 1/2″ gypsum should be added.

One commenter stated that in § 3280.212(g) the reference to § 3285.201 should be changed to § 3285.301. The commenter proposed that a new paragraph (h) be added because a site-built, self-supported garage is considered an add-on per § 3282.8(j)(1) and does not affect the ability of the manufactured home to comply with the Construction and Standards.

Another commenter stated the Standards should be consistent with other building codes, such as the IRC. Instead of requiring that the fire separation be continuous from beneath the floor, through the attic space, to the underside of the roof sheathing/decking, the Standards should only state that the garage must be separated from the home with appropriate gypsum wallboard or equivalent. Manufacturers can determine whether the fire separation should be continuous from the floor, through the attic space, to the roof sheathing or decking or if it is more appropriate to envelop the structure's garage side. Other building codes leave this to the builder's discretion and so should the Standards.

The commenter continued that HUD's proposed rule for factory or site construction of attached garages should emphasize the distinction between attached and self-supported structures. HUD should also revisit the fire separation requirements for attached garages. The commenter's suggested edits included clarifying that attached garages are not self-supported. Further, when a garage would be attached to and supported by the home, manufacturers should only be required to comply with the Standards' load provisions. They should not be expected to build homes that also meet the specific requirements of the various state and local jurisdictions, and confirming that a site-built, self-supported garage is considered an add-on and clarifying that add-ons do not affect a manufactured home's ability to comply with the Standards.

According to one commenter, the guidance provided in §§ 3280.212, 3280.213, 3282.8(j), and 3285.903(c) (Attached Garages, Carports and Add-Ons) appears contradictory and confusing. Sections 3280.212 and 3280.213 provide guidance on how manufactured housing should be prepared for the addition of garages and carports which is clearly within the scope of the Federal standards. These sections, along with § 3282.8, discuss load paths, providing conflicting information on where loads should be transferred. If the intent is to offer options, then the sections should be presented with an “or” statement to indicate they are options, as is included in the Data Plate requirements of § 3280.5. The commenter said who bears responsibility for approval and inspection of these attached accessory buildings and structures should also be clarified. According to the commenter, these structures should comply with the local building code and be inspected to that code by the local jurisdiction, given their designation as “attached buildings or structures” and not the extension of the manufactured home.

HUD Response: HUD agreed with most comments and has accepted all suggested textual changes to the standards that were submitted by the public. HUD modified the final Construction and Safety Standards accordingly.

HUD disagreed with the commenter that installation instructions are not required by this final rule, as it is specifically addressed through § 3280.212(g). Further, upon placing a label certification on each transportable section of a manufactured home, the manufacturer self certifies its compliance with the Construction and Safety Standards. Should the commenter seek additional changes to either manufacturer or IPIA requirements, the commenter is encouraged to submit comments through the MHCC process for consensus review and deliberation. It is not appropriate for HUD to integrate these changes at the final rule stage. HUD also notes that the added information required on the Data Plate more clearly identifies whether the home has been designed for an attached garage.

Subpart C, Fire Safety, Attached Carports

§ 3280.213 Factory Constructed or Site-Built Attached Carports

One commenter stated that the proposed rule should be modified to include attached patio covers and porch roofs which can easily exceed the size of a carport. The commenter also stated that current HUD policy under Interpretive Bulletin H-1-77 conflicts with paragraph (f)—there is no assurance that the manufacturer would be including these additional instructions.

Another commenter requested HUD delete the following: Paragraph (b) about maximum roof slope for the carport, on the basis that carports cannot exceed the height of the home; paragraph (c) on beam designs, on the basis that beam designs would be part of the approved design by the Design Approval Primary Inspection Agency (DAPIA); and paragraph (d) on shear wall and uplift strapping design, on the basis that the carport design would not be known.

One commenter stated that paragraph (f)'s reference to § 3285.201 should be changed to § 3285.301.

Another commenter said § 3280.213 for factory or site-built attached carports should emphasize the distinction between attached and self-supported structures and that striking unnecessary or superfluous rules would also streamline the requirements. The commenter's suggested edits include: Deleting the maximum roof slope requirement from the list of design characteristics for carports, because given that the height of the carport cannot exceed the height of the home, the carport's roof slope is never a relevant factor in home design; adding a provision that, as an alternative to specifying the unique design characteristics of the carport and the home, manufacturers may provide the maximum loads that the home is designed to resist from the carport; removing the provisions specifying where splices in the host beam can be located, because narrowly defining this provision with such detailed, prescriptive requirements could have unanticipated consequences, especially if there are continued advancements in anchoring technology. According to the commenter, specific design characteristics should remain subject to review and approval by the manufacturer's DAPIA.

The commenter's recommendations continued with: Removing the shear wall requirements for homes designed for Wind Zone II and III installations in favor of manufacturers specifying anchor requirements for uplift forces in Wind Zones II and III as part of the home's DAPIA-approved design, because if the manufacturer and its DAPIA specify these requirements at the design stage, the size of any attached carport would be limited by the load capacity of the anchor system installed in the factory. This would limit the design options available to any third party responsible for installing an attached carport at the jobsite; and removing the “cone of influence” provision, because this requirement is dependent on the type of anchor, and should be determined by the installer. The manufacturer should not be expected to know this information without knowing exactly where a manufactured home would be sited and how it would be installed; and confirming that a site-built, self-supported carport is considered an add-on and clarifying that add-ons do not affect a manufactured home's ability to comply with the Construction and Safety Standards.

Another commenter also supported deleting paragraph (c)(1), because this paragraph was covered in paragraphs (a) and (c), and additional details on the acceptable engineering load path are not required. The commenter also suggested deleting paragraph (d) because the load path requirements should apply to all wind zones as specified in paragraphs (a) and (c). The commenter also stated that the accepted engineer anchor test protocol does not test for cone of influence and it is not defined within the Construction and Safety Standards. Therefore, it should be removed from § 3280.213(f)(1).

HUD Response: HUD did not add requirements for patio covers and porch roofs, as such specific code change text and supporting information be submitted to the MHCC for consensus review and deliberation. It is not appropriate for HUD to integrate these changes at the final rule stage. Further, HUD disagreed with comments that installation instructions are not required by the standard, as it is clearly addressed in §§ 3280.213(b) and (e). Upon placing a label certification on each transportable section of a manufactured home, the manufacturer self-certifies its compliance with the Construction and Safety Standards.

HUD notes the added information required on the Data Plate more clearly identifies whether the home has been designed for an attached carport. HUD agreed with all comments providing specific textual changes and HUD modified the standards accordingly.

Subpart D, Body and Frame Requirements

§ 3280.305 Structural Design Requirements

One commenter stated that proposed § 3280.305(h)(5) expands areas of construction that could be deferred to the job site and imposed on the installer under “On-Site Completion Requirements.” The commenter stated that installers were not included in deliberations on the proposed changes, and that since the On-Site Completion rule is relatively new, and given that HUD has failed to monitor or measure compliance, this provision should be deleted until the success of the “On Site Completion” process can be evaluated. Another commenter stated that HUD should delete the words “connections between sections,” after “hinged roof sections,” and before “sheathing,” in paragraph (h)(5) because connections between sections is covered as part of standard installation.

Another commenter stated that paragraph (h)(5)(iii) requires inspection at an installation site in stages but does not clarify who would provide inspections. The commenter also suggested that HUD clearly define “inspection of the work at the installation site in stages,” and stated that this new requirement would add costs to the home, drive up the cost of affordable housing, and would financially burden the commenter.

Two commenters stated that HUD strike §§ 3280.305(h)(5) (iii), (iv), and (v), because these proposals generally apply to onsite installation and appear to overstep Subpart D's bounds. The commenters believed these requirements, if necessary, would be more appropriate under Part 3282, Subpart M, “On-site Completion of Construction of Manufactured Homes.”

HUD Response: HUD disagreed with the commenter that revisions to this standard expand areas of construction that can be completed on site. The changes to this standard were already implemented with the On-Site Completion of Construction Rule and these changes are conforming. Further, HUD conducted limited monitoring of procedures and approvals related to On Site Completion of Construction and has not concluded any adverse or significant findings.

HUD modified this section to address other comments received including removing any references to installation activities. HUD also modified the inspection requirements but has retained the intent that inspections occur prior to covering up additional aspects or otherwise allowing for inspection panels so that inspection can take place. This aspect is important to assure that the work completed on site conforms to the design standards, so that the home is completed in accordance with the Construction and Safety Standards, and the home is not taken out of compliance through the work done at the home site. Further, these standards are established to work in concert with the regulations for On Site Completion of Construction and will help to ensure that appropriate designs are provided to address the work that is expected to happen in the factory, the work that is expected to happen at the home site, and the factory and or inspections at the site necessary for conformance.

§ 3280.307 Resistance to Elements and Use

A commenter stated that the expansion of field installation of exterior coverings means the requirement for the manufacturer to provide all needed materials (siding, fasteners, channels, etc.) should be added to this list. Another commenter agreed and suggested adding “and the required materials” after “Complete installation instructions.” A commenter suggested adding attached garages to the list of exemptions in paragraph (e), given the amount of onsite work required to complete the installation of an attached garage, and as long as the manufacturer is complying with HUD's list of conditions.

HUD Response: HUD reviewed and generally agreed with the comments. HUD modified the standard accordingly.

Subpart F, Thermal Protection

§ 3820.504 Condensation Control and Installation of Vapor Retarders

One commenter stated that the proposed requirements under §§ 3820.504(b) and .506(c) are not needed, and HUD should delete them. The commenter stated its mating walls are located in a conditioned area, gaskets are installed in the factory to prevent air infiltration, and the commenter has not witnessed a mating wall with damage from condensation.

Another commenter stated that mating walls are interior walls and should not be treated as exterior walls which require a vapor barrier. Furthermore, many homes have single mating walls, and this section does not define on which side the vapor barrier should be applied.

Another commenter stated that HUD should delete these proposals until certain issues are evaluated. There will be a concern if the connection between floors is not effectively sealed from allowing cold outside air to enter between the ceiling of the first floor and floor system of the upper floor. If cold air is entering this area, a vapor retarder should be applied to the ceiling on the first floor. Another concern would be if the bottom board is still required to be placed under the upper floors, this may add to additional condensation between the floors if the vapor retarder is not installed on the ceiling on the lower floor.

HUD Response: HUD disagreed with the commenters regarding the need for §§ 3280.504(b) and (c) to be deleted or amended, and that the affected walls are interior walls. These commenters may not understand that the subject standards apply to the (fire) walls separating attached manufactured homes; rather than, mating walls between two sections of the same manufactured home. Multi-story manufactured homes have been designed and built for more than two decades prior to the rulemaking and under Alternative Construction processes. These homes have been designed and built, and significantly, HUD has not received information indicating these homes, without a ceiling vapor retarder on the first floor, are not performing.

§ 3820.506 Heat Loss/Heat Gain

Two commenters suggested revising paragraph (c) by replacing “the mating wall of each” with “the fire separation wall between each.” Mating walls between two or more sections of a multi-section home are not the same as firewalls separating two or more attached, single-family manufactured homes. Mating walls are aligned at installation to create a cohesive single-family residence—they are not exterior walls. However, fire separation walls, which separate attached single-family homes, should be classified as exterior walls because they act as a health-safety barrier between distinct residential dwellings. The commenters believed these edits clarify the distinction between mating walls and fire separation walls.

HUD Response: HUD reviewed and generally agreed with the comments. HUD modified the standard to incorporate the public comment where those changes have not significantly altered the intent as proposed.

Subpart G, Plumbing Systems

A commenter suggested clarifying the definition of “indirect waste receptor,” a new term being introduced to the Standards. Second, in § 3280.608, strike “Hangars” and replace it with “Hangers” as in the original. Third, by incorporating additional safety considerations from the Uniform Plumbing Code, the commenter saw an opportunity to protect the general public from the risk of burn or scald. The commenter believed a home's relief drain, should it terminate outside the home, must terminate between six and twenty-four inches above the finished grade and face down at termination; high enough to prevent backflow, but low enough to reduce the risk of injury or accident.

HUD Response: HUD reviewed and generally agreed with the comments. HUD modified the standard to incorporate the public comment where those changes have not significantly altered the intent as proposed.

§ 3280.609 Water Distribution Systems

One commenter stated that the requirement that installers extend water heater relief valve piping to beyond the skirting of the home would very likely create an imminent safety hazard because it carries superheated, pressurized water, so it should be deleted. Another commenter stated that if the relief valve is directed to outside the crawl space, there would be a possibility of personal injury to those nearby. The commenter explained that water heater manufacturers do not allow additional piping to be installed directly on the pressure relief valve. They require “air gaps” when directing into additional piping. The commenter concluded that HUD should reject these changes.

Another commenter stated that HUD should add discharge pipe turndown requirements taken from the Uniform Plumbing Code which adds a higher level of scald protection. This revision will increase consumer safety.

Two commenters proposed changes to HUD's regulatory text.

HUD Response: HUD reviewed and generally agreed with the comments and addressed the protections to residents by accepting comments regarding relief pipe turndowns. HUD also modified the standard to incorporate the public comment where those changes have not significantly altered the intent as proposed.

§ 3280.612 Tests and Inspection

One commenter opposed the changes to this section because they would reduce the required pressure needed to perform water supply testing and, as a result, a revision of the manufacturers' installation instructions would be needed along with oversight by the IPIA agencies to assure that the proper instructions are provided with the home. Another commenter recommended that, in the last sentence, “potable water source” should replace “potable source of supply.”

HUD Response: HUD generally agreed with the comments regarding wording changes to the standard. HUD modified the standard to incorporate the public comment where those changes have not significantly altered the intent as proposed. HUD disagreed with opposition to the proposed change as the changes have been vetted by the MHCC and are consistent with many state requirements for testing potable water supply systems. While this change may require revisions to manufacturers' installation instructions, the system of design approvals will ensure the instructions conform to the revised requirements by the rule's effective date.

Subpart H, Heating, Cooling and Fuel Burning Systems

§ 3280.705 Gas Piping Systems

One commenter suggested HUD eliminate “hard pipe” in paragraph (i)(8)(iii), as the industry uses a flex gas connector and not a quick-disconnect.

HUD Response: HUD reviewed and generally agreed with the commenter and modified the standard to incorporate the commenter's proposed change.

§ 3280.709 Installation of Appliances

A commenter stated that §§ 3280.709(a) and 3280.711 require that manufacturers currently ship two sets of installation instructions for each appliance with every home; the MHCC voted to strike this requirement from section § 3280.709(a) by letter ballot in 2015 (Log #92).

Some commenters noted the importance of inspection but stated that it is unclear who is to perform on-site inspections and testing related to paragraph (a)(1)(ii). One commenter stated that HUD should clarify that the installation is to comply with the local building code requirements and be subject to inspection by state or local code officials. This commenter noted that the language in § 3280.709(a)(1) would allow for the installation of direct vent space heating appliances on-site following approved instructions and the installation and inspection procedures provided.

A commenter was concerned with changes to the vent system termination provisions in paragraph (d) because the commenter was unaware of any health-safety risks that would necessitate expanding the permissible range from 3 to 10 feet. The commenter stated the IRC has a similar requirement, but it only applies to the vent system of a fuel-burning appliance. Consequently, the commenter recommended adding the clarifying phrase “of fuel-burning appliances.” In addition, the commenter replacing the phrase “habitable areas” with “habitable rooms” because this term is defined in the Standards.